Types of Cable Trays 1

Types of Cable Trays –

Purpose, Advantages,Disadvantages

Cable tray systems are alternatives to wire ways and electrical conduit, which completely enclose cables.

Cable trays are capable of supporting all types of wiring: such as

- High Voltage Power Lines.

- Power Distribution Cables

- Control cables

- Telecommunication cables

- Fiber Optical Cables

Purpose:

Cable trays are components of support systems for power and communications cables and wires.

A cable tray system supports and protects both power and signal cables and facilitates upgrading,

expanding, reconfiguring, or relocating networks.

Most of the cable tray systems are open, allowing efficient heat dissipation and easy access for replacement and repairs.

Although typically suspended from ceilings or affixed to walls, some cable tray systems are suitable for underfloor use.

Types of Cable Trays:

The following are popular cable tray types.

- Ladder-type

- Perforated type

- Solid bottom type

- Wire mesh

- Channel type

An engineer or designer will usually specify the type of cable tray that has the features to suit the project.

It depends on the situation and the environment.

The selection of cable tray depends upon the number of cables, size, spacing, and weight of cable in the tray.

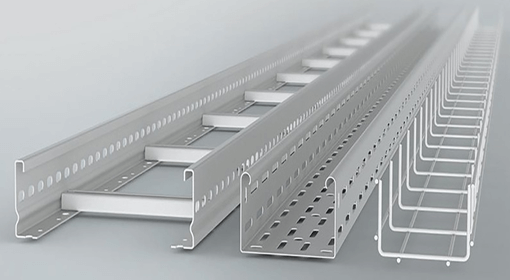

Ladder Cable Tray

Ladder Cable tray

Ladder Cable tray

has two side rails connected by rungs.

This type of cable tray is effective because the ladder rungs give you easy accessibility to the cables, from the top or bottom.

The rungs of the ladder cable trays provide convenient anchors for tying down

the cables in the non-horizontal cable tray runs or where

the positions of the cables must be maintained in the horizontal cable tray runs.

Perforated Cable Tray

Perforated cable tray Consists of a ventilated bottom with side rails. It provides more support to cables than the ladder-type,

Solid-bottom Cable Tray

Solid-bottom Cable trays for fiber-optic cable installations where drooping of cables may affect system performance, solid-bottom (non-ventilated) cable trays are preferred.

Solid-bottom Cable trays for fiber-optic cable installations where drooping of cables may affect system performance, solid-bottom (non-ventilated) cable trays are preferred.

However, the main reason for selecting solid-bottom trays is a concern for electromagnetic/ radio-frequency interference protection.

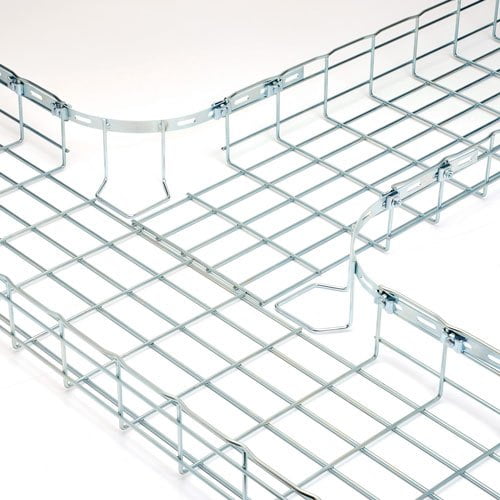

Wire Mesh Cable Tray

Wire mesh cable tray, also called basket cable tray, is a kind of cable tray made of stainless steel wires by welding wires together, forming a basket-like mesh

Wire mesh cable tray, also called basket cable tray, is a kind of cable tray made of stainless steel wires by welding wires together, forming a basket-like mesh

Cable Trays are mainly used for low voltage, telecommunication, and fiber optic cables supported on short spans.

Channel Cable Tray

Channel cable tray nothing more than a metal tray that can be used for very small cable installations.”

Channel cable tray nothing more than a metal tray that can be used for very small cable installations.”

Materials

1. Metallic

Aluminum: Resists corrosion; excellent strength-to-weight ratio. Aluminum is most commonly used because it is lightweight.

Steel: Electric shielding; low thermal expansion

Stainless steel: Superior corrosion resistance; withstands high temperatures.

2.Non-Metallic

Fiberglass: Nonconductive; resists corrosion; lightweight

Precautions:

The most important issue is to ensure that the bend radius for the fiber-optic or coaxial cable is maintained within the standards.

Combustible dust and clutter may accumulate if the trays are not routinely checked and kept clean.

Advantages:

Less expensive: One of the big advantages that using a cable tray has that it costs a lot less than other methods of protecting wiring on the production floor.

Maintenance: Cable are instantly visible for maintenance checks, changing of cables is easy because cables can enter or exit the tray at any point of the system.

Safety: Regular housekeeping is important for safety, as cable trays are often installed in hard to reach places.

Disadvantages:

The solid bottom cable tray system has a disadvantage. In that moisture can build up in the cable trays.

Types of Tray Fittings

There are various types of fittings used in the manual tray installation.

Sometimes companies does not provides fittings, that situation electricians used to cut a trays with using jigsaw machine.

Fittings: T-Joint, bend or elbows, crossover, inside riser, outside riser, reducer, coupler, joint plate, unistate, spring and nut bolts.

Tools requirement: Spanners, hammer, screwdriver, jigsaw for manual tray cutting.

Installation of Electrical Cable Tray

Trays for supporting cables are recommended for use in warehouses, industrial plants and equipment room,

cable trenches, shafts in the building, etc. Steel cable trays,

accessories and supports normally be hot dip galvanized or PVC coated and shall be either of the perforated type or ladder.

The cable trays shall have adequate strength and rigidity to support the cables installed.

The tray shall be provided with upstands on both sides. All fittings, T-joints, elbows, couplers etc.

shall be of substantial sections of the same quality as the trays.

Cables shall be fastened securely by purpose made clips, cleats or saddles. Installed in outdoor locations,

where in the cables are exposed to the sun shall be provided with sun shade covers secured to the trays adequate ventilation and as recommended by the manufacturers.

Types of Trunking

Cable trunking is a manufactured enclosure for the protection of cables.

Purpose of use: Where applicable, surface and underground(duct) areas.

Cable Trunking Sizes: 50 mm, 75 mm, 100 mm, 150 mm, 200 mm, 225 mm and 300 mm.

Types of Trunking Fittings: Bend, coupler, T-joint, endcap.

Types of Trunking

Adaptable trunking shall be used for power cables and data cables to run parallel in two different compartments with partition.

Mini trunking is suitable for surface wiring work indoors where necessitated,

either due to aesthetic or technical requirements such as case of extension of existing wiring.

PVC (to know full form) insulated or other insulated cables shall be used in this type of installation.

Wherever data cables are used for information outlet, trunking shall be used.

This system using PVC trunking shall be adopted in residential building, or office building where there is a need of tidy wiring system.

This type of trunking for distribution of voice data and power should be used

for cable management and should accept data socket and power socket or other wiring accessory like switches, indicators etc.

Preferred size of PVC trunking should be 25 x 16 mm, 32 x 16 mm,

40 x 25 mm, 40 x 40 mm and for adaptable trunking it should be 100 x 34 mm or 100 x 50 mm or 160 x 50 mm or 200 x 50 mm.

Installation Method of Trunking

Metallic or Pvc trunking shall be fixed by means of suitable screws to approved type of asbestos or fibre fixing plugs, at intervals not exceeding 60 cm for all sizes for mini trunking.

Incase of adaptable trunking, the screwing system shall be such that weight of the trunking and hold firmly on the wall or ceiling.

On either side of joints, the distance of the fixing arrangement shall not exceed 15 cm from the point.

All trunking body shall be fixed directly on wall or ceiling as above.

Trunking shall be used only on dry walls and ceiling,

avoiding outside walls as far as possible and shall not be buried in the walls not fixed in proximity to gas,

steam or water pipes.

Trunking shall be with pill off cover for protection against dust.

Pill off cover shall be removed only on completion of painting of walls.

PVC Trunking (Casing & Capping)

The wire ways in straight runs should be in single piece as far as possible so as to avoid joints.

Trunking shall be of 2 m or 3 m standard for the ease of installation.

All joints shall be scarfed or cut diagonally in longitudinal section,

and shall be smoothed down by fitting to make the joints a very close fit as far as possible and without burrs.

They shall be screwed at joints with with two or more screws as would be necessary.

Joints arising out of the bends or diversion shall be done using standard accessories like internal angle,

external angle elbows, T-joint and end caps.

For the separation of data cables and power cables there shall be partition in both trunking and accessories.

In-riser and out-riser shall have variable angle for alignment at the wall corners.

Final word

Hope you understand this article about the

Cable Tray Sizes & Types | Types of Trunking.

Please share your experience through the comments.

Your comment can help me to improve my site updates.

And if you think our post was something worth reading,

then please share it with your social media friends.

electric fuse

We are pleased to have you visit our pages on social networking sites,

where we publish exclusive offers on our website.

Our Facebook page here .

Our Twitter account is here .

Leave a Reply

You must be logged in to post a comment.